Aeration

O2Max

High efficiency aerator

Spaans Babcock developed the third generation aerator: After a long period of testing, the ideal design was developed. A complete new design which ensures a high efficiency, a huge mixing effect and a very smooth running with less vibration to the bridge and drive unit. The new O2Max is designed on the basis of the latest know-how (knowledge) on surface aeration and beats the old problems with this kind of aerators.

The O2Max is approved for the Carrousel® system by DHV.

| Water Depth: | Because of the strong mixing power of the O2Max, in most cases a system without sludge settlement can be guaranteed up to 6 meter water depth. |

| Aerosols: | Studies prove that the amount of aerosols is obviously lower than with fine bubble aeration. In addition protection systems are available. |

| Noise load: | Simple covers are available for the drive unit. For the Aerator different covers and bridge systems are available. |

| Energy-efficiency: | Until 4 meter water depth absolute the most economic aeration system. In larger water depths, it will be often an economical solution, but each single case must be proved. |

Advantages:

|

| Spaans Babcock constructs the largest and most high-performance surface aerators with achievements of up to 500 kg O2/h per machine. |

Applications

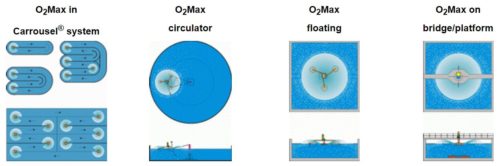

The O2Max is especially suitable for Carousel® systems. Due to its high oxygen input and propulsion properties, it is often the most economical solution for this system. Extreme propellers are often not necessary, however, this will be required on a case-by-case basis.

O2Max floating

In cases where no bridge or platform construction are possible due to large water level changements, the installation with floaters is a possibility. Three floaters on a heavy load construction will allow the aerator to float itself.The aerator will be kept in its position by heavy steel cables. Installation is possible in all kind of square and round tanks.

O2Max circulator

The circulator is a construction of a floating aerator, connected in the middle of the tank and is moving self propelled on a circular path system through the tank. The system can be used for low load systems in all kinds of tanks. Installation is possible in relative large tanks.

The O2Max consist of:

- aerator impeller

- vertical shaft and coupling

- foundation plate

- gearbox

- electric motor

The aerator impeller is a low speed, non-clogging and open type. The aerator is a heavy steel construction to withstand stresses created by mixed liquor motion and will be adequately anchored and supported to the bridge of the aeration tanks.The impeller consist of a flat plate with curved blades beneath the plate in order to obtain maximum efficiency and to suffer minimum friction losses between blades and water.

The O2Max design will comply to the following:

|