Obnavljanje

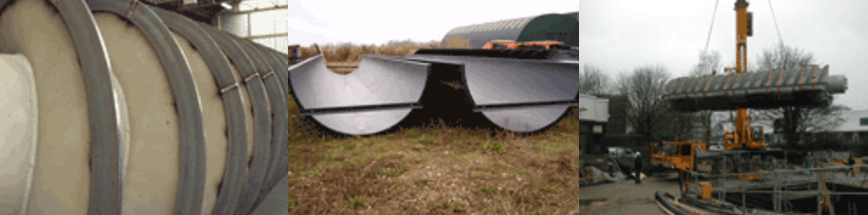

Refurbishment & overhaul of screw pumps

Screw pumps which have been in operation for many years can be subject to wear in the trough and on the screw pump body. The cause of this wear can mainly be found in strongly grinding materials like sand and gravel in the sewage. An overhaul of the screw pump body and the trough has to be considered when an increased gap between the screw pump body and the trough can be perceived which has a negative influence on the efficiency and therefore requires an increased capacity of the screw pump.

The following refurbishment options can be considered:

- Refurbishment of the screw pump body and renewal of the concrete trough

- Refurbishment of the screw pump body and replacement of the concrete trough by a steel liner

- Refurbishment of the screw pump body and put in the existing trough with a new self supported steel liner, adapted to the screw pump body. Here no, or only minor, civil costs are incurred

Working procedure of the different options:

To a)

- Dismantling of the screw pump and transportation to the factory in Balk, the Netherlands

- Blast cleaning of the screw pump body

- Restoring and/or, if necessary, part renewal of the flights of the screw pump

- Adjustment of the outside diameter on a lathe to the required size

- Checking the roundness of the screw pump and balancing and re-machining the flanges

- Applying new coating

- In the meantime removal of the old concrete trough screed

- Transportation of the screw pump body to site and installation of the renovated screw pump body and the refurbished bearings

- Re-screeding of the concrete trough

- Setting the refurbishment screw pump into operation

To b) – Point 1 – 7 as above

- Building the new steel trough liner together with the screw pump body

- Transportation and installation of the screw pump body and steel liner and the refurbished bearings

- Backfilling / grouting around the steel trough liner

- Setting the refurbished screw pump into operation

To c) – Point 1 – 6 as above

- Building the new static self supporting steel trough liner together with the screw pump body

- Transportation and installation of the screw pump body and steel liner and the refurbished bearings

- Setting the refurbished screw pump into operation. Because of the self supported static steel trough liner no backfilling is required. The old concrete trough does not need to be removed because the new screw pump has a slightly smaller diameter and therefore fits in the existing trough

In all variants the following must be taken into account:

- Refurbishment of the screw pump should not take place at site but rather in the factory in Balk, because otherwise no guarantee can be given over the quality of the welding, the shot blasting and the corrosion protection.